talk about bearing

2- BEARING material ,Bearing

damage cause

Top end bearing - Crosshead engine –

transmit load from cross head pin to connecting rod , allow relative movement

of con rod and cross head pin, Trunk pistion engine- transmit load from gudgeon

pin to con rod , allows relative movement of con rod and gudgeon pin

Bearing lubrication - Gudgeon pin and Crosshead

bearing

Fluid -film lubrication depends on the fluid's viscosity, that is, its

resistance to internal motion. This resistance is due to cohesion of the molecules within the

fluid; it occurs whenever there is internal motion, irrespective

of whether or not this motion is caused by a change in the fluid's shape. A

liquid adheres to the surface of a solid in

contact with it. The motion of the solid at the interface causes internal

motion in the liquid, which then

resists the force acting on the solid. When a shaft rotates in a journal

bearing with suitable running clearances,

resistance to motion (or 'viscous drag') carries the oil with the journal round

the bearing. The hydrodynamic conditions, that then come into operation, cause

the journal to adopt a position, relative to the bearing, in which the

running clearance on the loaded side diminishes and a high fluid pressure is

built up. Provided that the oil is delivered

to the bearing at a rate sufficient to compensate for end or side leakage, a fluid film established in this manner will

withstand severe loading. The rate at which oil escape's from a bearing depends mainly on its viscosity, the bearing

clearances and the arrangement of the oil distribution grooves. Leakage is also influenced by the condition of

the bearing and the load applied to it. Thus, by suitable bearing design and by supplying oil of the correct

viscosity at a rate above the minimum required, it is possible to maintain a lubricant film that will not rupture under

the designed running conditions. Lubrication of the gudgeon-pin bearing of trunk-piston engines is far more

difficult than that of the main, big end or thrust bearings and lubrication failure is a common cause of

trouble. Seizure of the pin can lead to bending of the connecting rod or

scuffing of the piston. The gudgeon-pin subjected to heavy loads and because of

the heat conducted from the piston, operates at relatively high temperatures.

Moreover, the small oscillatory angular motion restricts the build-up of an oil

film. In 4 stroke engines, satisfactory lubrication is promoted by cyclic lifting

of the gudgeon pin within the bearing that takes place towards the end of the

exhaust stroke. This movement, caused by

forces of inertia, accompanies reversal of the direction of load and enables

the bearing to 'breathe'. So the

clearances are refilled with oil. In the two stroke engine, there is no

'breathing',. since the bearing

load, though fluctuating is continuously downwards as in the main bearings.

Various special arrangements are therefore used to ensure satisfactory

lubrication of gudgeon pins. One method is to increase the bearing area to such an extent, that the hydraulic load due

to oil pressure is able to force the pin and journal out of contact with each

during the minimum loading period. These conditions of gudgeon-pin lubrication also apply in general to the crosshead

bearings of large, low-speed, two-stroke crosshead engines.

Owing to the oscillating movement on the bearing, it is

very difficult to establish full hydrodynamic lubrication, and conditions of boundary lubrication

usually prevail. Crosshead engines are therefore subject to local overloading and failure of the lubricant film,

leading in turn to fatigue cracking and possible break-up of the surface. Various means have been adopted to improve

lubrication of crosshead bearings. Manufacturers attempt to keep the specific loading as low as possible, for example by

a large crosshead pin diameter, and by allowing self-adjustment of the

bearing housing, to compensate for deformation of the crosshead pin and the head of the connecting rod. This flexibility

maintains a uniform load distribution. In addtion to reduced loading and

improved lubrication, other important factor in the maintenance of bearings are

the alignment between them and the surface

finish of the crosshead pin.

By providing of hydrostatic lubrication to X head bearing , such as

Fitting of reciprocating positive displacement L.O pump , utilized by movement

of con. rod , Arrange booster pump to supply X head bearing up to 16 bar.

To

combat the difficulty of Fluid -film lubrication - Sulzer engine- conjugate

deflection(crosshead pin bored at center), continuous full length bottom half

of crosshead bearing(MAN B&W), eccentric bored bearing & machining

shell (Fiat engine), large diameter stiff crosshead pin L/D ratio less( con rod

and crank throw ratio keep as low as to increase sliding velocity &

improved lub oil film), make cross head pin high degree of surface finish

<0.1 micron, thin shell bearing & improved material.

Man b&w crosshead

bearing -

The lower half of the bearing housing is formed by the top end of the

connecting rod. It supports the crosshead pin over its entire length, the

piston rod being bolted to the top half of the crosshead pin through a cut out

in the bearing top half. Oil supply to the crosshead is via a telescopic pipe

from the main LO supply at a pressure of about 2.5 bar.

Bearing

Type -The type of bearing used in the crosshead assembly is a thin

shell (insert) bearing . The lower shell is a trimetal shell, i.e. the

shell is composed of a steel back with cast-on white metal and an

overlayer coating. The upper shell is a bimetal shell, as it does

not have the overlayer coating; both the upper and lower shells are

protected against corrosion with tin flash

credit to MAN B&W service letter

Bearing Function and Configuration- Because of the oscillating

movement and low sliding speed of the crosshead bearing, the hydrodynamic

oil film is generated through special oil wedges on

either side of the axial oil

supply grooves situated in the loaded area of the bearing.

The oil film generated in this manner can be rather

thin. This makes the demands for pin surface roughness and oil wedge geometry

very important parameters for the assembly

to function. A further requirement is effective

cooling which is ensured by the transverse

oil grooves. The pin surface is superfinished. The lower shell is executed with a special

surface geometry (embedded arc) which extends over a 120 degree arc, and

ensures a uniform load distribution on the bearing surface in contact with the

pin. The lower shell is coated with an

overlayer , which enables the pin sliding geometry

to conform with the bearing surface.

In MAN B&W engines, a set of channels have been

machined in the lower crosshead bearing, in

which the cooling oil can pass. The geometry is

designed in such a way that all the loaded square centimetres of the pin are

flushed with cooling oil twice every engine cycle. In contrast, the Sulzer

crosshead has a plain lower bearing without channels. In order to inject oil

between pin and bearing, they have to supply oil at a much higher pressure. The

injection will take place at around 20 degrees crank angle before TDC, where

the cylinder pressure is still low and upward inertia forces on piston is still

high. There is a short interval, in which the bearing pressure is lower than the

oil pressure.

cosmetic wiping - this wiping is of a cosmetic

nature; but it can sometimes cause blockage of the oil-wedges that normally

build up the oil film to the "pads" inside the bearing, Disturbance of the oil film build-up inside

the bearing could result in slight fatigue damage just behind the blocked area

of the oil-wedge. If the phenomenon is observed at an early stage during

inspections. The problem is solved by removing the wiped lead from the

oil-wedge.

Sulzer RTA

96

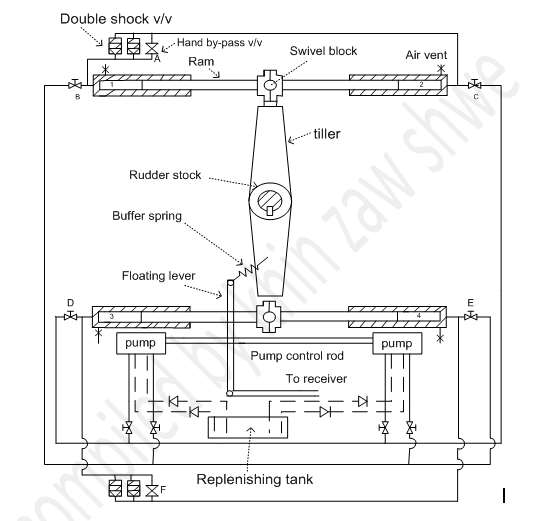

Main bearing oil system

Main bearing oil is also used to cool the working

piston via a toggle lever at an

operating pressure of 4.0 BAR TO 4.8

bar. The main bearing and crosshead oil systems are interconnected through a

non-return valve . The integrated axial detuner, and if there is a vibration

damper as well as an electrical balancer built-on at the free end (by 6 Cyl.

engines), are supplied and cooled with bearing oil.

Should the crosshead lubricating oil pump fail, then the crosshead bearing oil system

is supplied with main bearing oil pressure. Under such conditions the engine

can only be operated at reduced load (Load Indicator Position, LIP max.

4.5).

Crosshead bearing oil system

The operating pressure of the high pressure oil is

10 to 12 bar. The lubrication of crosshead pins as well as of connecting rod

bottom end bearings is effected through toggle lever.

The oil supply for the exhaust valve actuator pumps

to the exhaust valve control passes from

the crosshead bearing oil system through the air separator . For actuating the

exhaust valves, the oil pressure is raised to about 160 bar by the actuator

pumps .The reversing servomotors on the camshaft are actuated by crosshead

bearing oil.

Main bearing – support crankshaft and keep it aligned. To

remove heat produced by friction.

Bottom end / crankpin bearing – transmit load

from con rod to crankshaft. Allow relative movement of con rod & journal.

The MC engines were originally designed with

white metal bearings for the crosshead, crankpin and main bearings. The main

bearings were of the so-called thick shell design,whereas the crosshead

and crankpin bearings were of the thin shell design.

Thin shell main bearings

The development towards higher specific engine

outputs has resulted in the gradual introduction of the thin shell design for

the main bearings. Sn40Al (tin-aluminium), which has been applied with great success

on the main bearings for the smaller two-stroke engines, has been introduced on

the S46-70MC-C engines, on which good service has been experienced .In addition

to the above, an advantage of the thin shell design is the reduced risk of

fretting-corrosion between the main bearing saddle and shell when the bearing

housing is well designed. Running-in on testbed and during sea trials has in a

number of cases caused light seizure of Sn40Al main bearing shells on the

S-MC-C engines. This seizure can be avoided either by prelubrication with

grease or high-viscosity oil, or by PTFE-coating of the running surface of the

shells. The Sn40Al bearings have been introduced on the engine with the same

well-proven specific load level as that for white metal bearings. (A thin shell

bearing design was introduced to more recent engine types. The main bearings of

the small and medium bore models (S46MC-C to S70MC-C)are lined with AlSn40 and

provided with a PTFE running-in coating as standard.

The bearings of the large bore models are lined with

white metal.)

Nip – the external circumference of

a pair of bearing shell is slightly larger than the bore of housing. This

difference is called nip.

Locating tangs - allow correct axial

positioning of bearing shells thereby ensuring alignment of oil transfer

passages and clearance between the ends of the bearing and crankshaft fillets.

The tang is located in a corresponding recess in the housing and must be a

clearance fit, otherwise the bearing surface may distort. It is also advantageous

to relieve the tang below the level of the bearing joint face, thus reducing

localized pressure on the tang during assembly. Tangs are not intended to

resist rotation of the bearing shell; that is achieved by the contact pressure.

If, under seizure conditions, this contact pressure cannot prevent rotation,

the tangs are either sheared or flattened.

Cause of thin

shell bearing shifting

– 1-defective tag or improper fitting precedure, 2-insufficient nip clearance,

3-suddenly applied extreme load(pounding), 4-incorrect size of bearing use,

5-due to overtightening bolts(elongation of bolts), 7- friction force from back

of the shell and keep. The overall thickness/diameter ratio is not critical,but

typically varies from 0.05 at 40 mm diameter to 0.02 at 400 mm

Interference fit

or bearing crush

- On assembly the excess peripheral length creates a circumferential stress

around the bearing, and a radial contact pressure between the bearing

back and the housing bore. This contact pressure

resists relative movement, thus preventing fretting. Unfortunately, there is no

theoretically correct level; housings with high flexibility require more

contact pressure than stiffer ones. On early engines, having thin shell

bearings, a contact pressure as low as 2MPa was usually sufficient to resist

fretting, but as engine ratings increased, and housing stress analysis became

more sophisticated, higher pressures became necessary, often reaching 8-10 MPa

today. In these very high interference fit assemblies, particular care has to

be taken to ensure that the joint face clamping bolts have sufficient capacity

to assemble the bearing, and to resist dynamic separating forces generated by

engine operation.( need to follow the instruction to tighting correct hydraulic

pressue at con rod bolts)

Thick shell main bearings (Optimum Lemon Shape (OLS) bearing

with flexible edges)

The design of the thick shell bearings has been

updated in order to ensure reliable performance. The major updates are

summarised in the following. Optimum Lemon Shape (OLS) shells,have been

introduced to increase the minimum oil film thickness. optimum lemon shape

(OLS)-type main bearing as an evolution of the Mark 5 bearing type, featuring

reduced top and side clearances.

credit to MAN B&W service letter

Flex –Edge thick-shell main bearing design.

SL03-414/AAB-Engine types: S/L50-80MC

Flex-Edge. Design

is fully interchangeable with previous types and provides an increased

margin against fatigue damage occurring in the edge area. There have been a few

reports of local bearing fatigue damage still occuring near the bearing shell

edges, in a few highly edge-loaded main bearing positions. New, advanced

calculations, including journal tilt and housing deformation, have provided

detailed information on the load pattern mechanisms of the main bearings. The

calculations indicate that a certain radial flexibility of the bearing edge

will

significantly increase the minimum oil film

thickness near the edges. Likewise, the maximum oil film pressure near the

edges will be reduced. The Flex-Edge design feature has been tested with

success, for more than a year, in positions which initially suffered repeated

problems.

The flexibility has been achieved by machining a 3

mm deep round-edged groove on

the back of the shell, with a width equal to the

thickness of the bearing shell, thus

avoiding contact with the bearing support in this

area. The unsupported part of the shell will flex slightly when load is

applied, thereby increasing the effective bearing area in situations where the

centrelines of the shaft and the bearing are not in alignment. A further

feature is static deformation of the unsupported part, which occurs when

tensioning the bearing housing..

Apart from the flexible edges, the properties of the

bearing are similar to those of the Optimum Lemon Shape type. This design

provides a larger safety margin in the event of geometrical

non-conformities. The deformation ensures a

controlled and smooth convex shape, 10-20 μm larger bore toward the edges.

Calculations confirm that such a shape further increases the safety margin

against high edge-loading.

Bearing

Metals

Tin

based White Metal (There is no interlayer in

white-metal based bearings)- Tin-based white

metal is an alloy with minimum 88% tin (Sn), the rest of the alloy composition

is antimony (Sb), copper (Cu), cadmium (Cd) and small amounts of other elements

that are added to improve the fineness of the grain structure and homogeneity

during the solidification process. This is important for the load carrying and

sliding properties of the alloy. Lead (Pb) content in this alloy composition is

an impurity, as the fatigue strength deteriorates with increasing lead content,

which should not exceed 0.2 % of the cast alloy composition. The fatigue strength of the basic

white metal composition can be increased by adding

cadmium, which goes into solution

in the matrix, and by adding trace quantities (0.1

per cent) of chromium, which refines the distribution of the copper-tin

compound. Tin based white metal is used in the main bearings, crankpin

bearings, crosshead guide shoes,

camshaft bearings and thrust bearings because of its

excellent load carrying and sliding properties.

Tin

Aluminium (AlSn40)-

In AlSn40 bearings, the overlayer is always bonded to the bearing

metal by a very thin interlayer of Ni (nickel), or Ag (silver).

Tin aluminium is a composition of aluminium (Al) and tin (Sn) where the tin is

trapped in a 3-dimensional mesh of aluminium. AlSn40 is a composition with 40%

tin. The sliding properties of this composition are very similar to those of

tin based white metal but the loading capacity of this material is higher than

tin based white metals for the same

working temperature; this is due to the ideal combination of tin and

aluminium, where tin gives the good embedability and sliding properties,

while the aluminium mesh functions as an effective load absorber.Tin

aluminium is used in main bearings

and crosshead bearing lower shells.

Overlayers

- An overlayer is a thin galvanic coating of mainly lead (Pb) and tin

(Sn), which is applied directly (on to the white metal ) or,( via an

intermediate layer, on to the tin aluminium sliding surface of the bearing). The

overlayer is a soft and ductile coating, its main objective is to ensure good

embedability and conformity between the bearing sliding surface and the pin

surface geometry.

Flash

layer, Tin (Sn) - A flash layer is a 100% tin (Sn) layer which

is applied galvanically; the thickness of this layer is from 2 µm to 5 µm. The

coating of tin flash is applied all over and functions primarily to prevent

corrosion (oxidation) of the bearing. The tin flash also functions as an

effective dry lubricant when new bearings are installed and the engine is barred.

credit to diesel engine reference book

copper-tin-lead alloy bearing (lead

– bronze alloy ).

lead-bronze bearing linings were introduced when fatigue of white metal became

a serious problem. They are used in very highly loaded bearings because of

their high fatigue strength; their drawback is poor tribological

behaviour. That is why they require an electroplated

overlay in most applications. It is always overlay-plated, primarily to protect

the lead phase from corrosion but also because the alloy is relatively hard and

incompatible. Standard composition for con-rod and main bearings is 78 % Cu, 20

% Pb, 2 % Sn. The alloy is used with electroplated overlay or cast babbit

running layer

These bearings can be found in marine diesel medium

speed engines.

Material

|

Maximum loading

(MPa)

|

|

AlSn6Cu1Ni1

|

Aluminium alloys:

|

38

|

CuPb26Sn1.5

|

Lead-bronze alloys:

|

38

|

AlSn20Cu1

|

Aluminium alloys:

|

35

|

AlSn40Cu0.5

|

Aluminium alloys:

|

20

|

SnSb8.5Cu3.5Cd1Cr0.1

|

White

metal alloy

|

14

|

SnSb7.5Cu3.3

|

White metal alloy

|

12

|

PbSb 10Sn6

|

White metal alloy

|

12

|

General Bearing Requirements and

Design Criteria

Bearings are vital engine

components; therefore, the correct bearing design and the proper choice of

bearing metal is necessary for reliable engine performance. Bearing design

criteria depend on the bearing type and, in general, on:a) Bearing sliding surface

geometry.b) The surface roughness of

the journal or pin, which determines the permissible bearing pressure and

required oil film thickness. This is necessary to ensure effective and safe

functioning of the bearing.c) The correct flow of cooling oil to prevent heat

accumulation, which is obtained through a flow area, provided either through

the clearance between the journal

and the bearing bore or through axial

grooves in the bearing sliding surface.

The compactness of engines and

the engine ratings influence the magnitude of the specific load on the bearing

and make the correct choice of bearing metals, production quality and, in

certain bearings, the application of overlayer an absolute necessity.

Scraping of the bearing surfaces

is strictly prohibited,

except in those repair situations of oil wedges, tangential run out, bore

relief, removing ridges and high spots from wiped bearing as approved by

manufacturer.

Incorrect scraping has often

proved to have an adverse effect on the sliding properties of the bearing, and

can result in damage.

Bearing Design - Plain bearings for MC engines are

manufactured as steel shells with a sliding surface of white metal or tin

aluminium. Tin aluminium bearings are always of the thin shell design while the white metal bearings can either be

of the thick shell or thin shell design.The bearing surface is furnished with a

centrally placed oil supply groove and other design features such as tangential

run-outs, oil wedges and/or bore reliefs.

Tangential Runout - A tangential runout is transition

geometry between the circumferential oil supply groove and the bearing sliding

surface. This special oil groove transition geometry

credit to man b&w manual book

Bore Relief - The bearing sliding surface is

machined at the mating faces of the upper and lower shells to create bore

reliefs. Their main objective is to compensate for misalignments which could

result in a protruding edge (step) of the lower shell's mating face to that of

the upper shell. Such a protruding edge can act as an oil scraper and cause oil

starvation. Fig A-A above.

Axial Oil Grooves and Oil Wedges

- Oil grooves

and wedges have the following functions: a) To enhance the oil distribution

over the load carrying surfaces. (The tapered areas give improved oil inlet

conditions). b) Especially in the case of crosshead bearings to assist the formation of a hydrodynamic oil film between the load

carrying surfaces. c) To provide oil cooling (oil grooves). In order to perform

these functions, the oil must flow freely from the lubricating grooves, past

the oil wedges, and into the supporting areas ! where the oil film carries the

load.

credit to man b&w manual

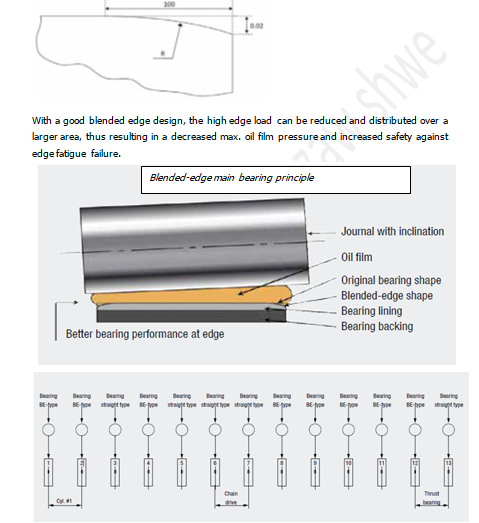

B.E DESIGN BEARING

The blended edge (BE) design was introduced on thin

shell white metal main bearings to better cope with crankshaft inclinations and

thereby increase its resistance towards edge fatigue failures.

The blended edge design is the corresponding thin

shell feature as for the thick shell flex-edge design in MC engines.

The BE design was introduced in 2004 and has since

that time successfully been used for new engines. Today, the BE white metal

bearing is featured in the S46, S50, S60, S65, S70, S80, K80, S90, K90 and K98

engine series.

Blended Edge Design

The blended edge design consists of a smooth radius

that allows the main bearing shaft to incline without risking touching the

bearing edge or causing high oil film pressure near the edge. The blended edge

is described by two dimensions, its length and its depth. The actual values

depend on engine size and configuration.

credit to man b&w service letter

With a good blended edge design, the high edge load

can be reduced and distributed over a larger area, thus resulting in a

decreased max. oil film pressure and increased safety against edge fatigue

failure.

credit to man b&w service letter

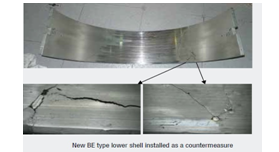

fatigue damage on the edge in bearing position No.

5, where a straight-edge main bearing was originally installed. The static

bearing imprint indicates that a concave geometry exists in this bearing

assembly, and a “straight-edge” check reveals that the main journal is concave.

In this case,

a BE lower bearing shell was installed, and the

issue was eliminated.

Lower

Oil Groove Removal(tangential

runout removal)

The oil groove feeds and distributes oil into the

bearing, but it also decreases the bearing area. On engines with high

horizontal load, the combination of blended edge and lower oil groove causes poor

fluid film conditions. The influence of the lower oil groove for the oil supply

is marginal and it is therefore considered better to remove the lower oil

groove to improve the horizontal bearing load capacity.

credit to man b&w manual

Spare Part Bearings

The trade off with blended edge bearings is its

decreased bearing load capacity when the inclinations are small and the bearing

force is very high. In such positions, “straight” cylindrical geometry bearings

are the better choice, and if blended edge bearings are specified elsewhere in

the same engine, it must be equipped with both plain and blended edge spare

parts. If an engine is delivered with a BE spare part bearing only, BE bearings

can be used in all

main

bearing positions.

This type of bearing has a steel

back with the required stiffness a) To ensure against distortion of the sliding

surface geometry, and b) To support the cast-on white metal in regions where

the shell lacks support, for example in the area of the upper shell mating

faces.The top clearances in this

bearing design are adjusted with shims, while the side clearances are a predetermined result of the summation of the

housing bore, shell wall thickness, journal tolerances, and the influence of

the staybolt tensioning force which deforms the bedplate around the bearing

assembly.

Thin shell bearings have a wall

thickness between 2% and 2.5% of the journal diameter.

The steel back does not have the

sufficient stiffness to support the cast-on white metal alone. The bearing must

therefore be supported rigidly over its full length. This type of bearing is

manufactured with a circumferential overlength (crush/nip) which, when the

shells are mounted and tightened up, will produce the required radial pressure

between the shell and the bearing housing. The maximum/minimum top clearance in

this shell is predetermined and results from a summation of the housing bore,

shell wall thickness, journal/pin diameter tolerances and, for main bearings,

the deformation of the bedplate from the staybolt tensioning force.

Cause of thin shell bearing

shifting

1-defective tag, 2-insufficient

nip clearance, 3-suddenly applied extreme load (pounding), 4-improper fitting,

5-correct size of bearing use, 6-due to overtighting bolts, 07-frictional force

from the back of shell and keep.

Top Clearance - Correct top clearance in main

bearings, crankpin bearings, and crosshead bearings is necessary to sustain the

required oil flow through the bearing, and hence stabilize the bearing

temperature at a level that will ensure the fatigue strength of the bearing

metal. In the main and crankpin

bearings, the clearance ensures the necessary space to accommodate the journal

orbit so as to avoid mechanical overload tendencies on the bearing sliding

surface (especially in the main bearing).The bearings are checked in general by

measuring the top clearances.In service, clearance measurements can be

regarded:1. as a check of the correct re-assembly of the bearing. For new thin

shell bearings and new/ overhauled thick shell bearings the clearances must lie

within the limits specified in the maintenance manual. 2. as an indicator to

determine the condition of the bearing at a periodic check ‘Checks without

opening-up’. In both cases, it is vital that the clearance values from the

previous check are available for comparison. Therefore, it is necessary to

enter clearances in the engine log book with the relevant date and engine

service hours.

Wear - Under normal service conditions,

bearing wear is negligible. Excessive wear is due to abrasive or corrosive

contamination of the system oil which will affect the roughness of the

journal/pin and increase the wear rate of the bearing.

The

reduction of shell thickness in the loaded area of the main, crankpin and

crosshead bearing in a given time interval represents the wear rate of the

bearing. Average bearing wear rate is 0.01 mm/10,000 hrs. As long as the wear

rate is in the region of this value, the bearing function can be regarded as

normal. For crosshead bearings, the wear

limit is confined to about 50% reduction of the oil wedge length.

Journals/Pins

Surface Roughness

Journal/pin surface roughness is

important for the bearing condition. Increased surface roughness can be caused

by: a) Abrasive damage due to contamination of the system oil.

b) Corrosive damage due to sea water

contamination of the system oil (acidic) or oxidation of the journals due to

condensate. c) Spark erosion (only in main bearings).

With increasing journal/pin

roughness, a level will be reached where the oil film thickness is no longer

sufficient, causing metal contact between journal/pin and the bearing sliding

surface. This will cause white metal to adhere to the journal/pin, giving the

surface a silvery white appearance. When

such a condition is observed, the journal/pin must be reconditioned by polishing,

and the roughness of the surface made acceptable. In extreme cases, the

journal/pin must be ground to an undersize.

Limits

to surface roughness

The surface roughness should

always be within the specified limits.1. For main and crankpin journals:

a) New journals 0.8 Ra

b) Roughness approaching 1.6 Ra

(journal to be reconditioned).

2. For crosshead pins:

a) New or repolished 0.05 Ra

b) Acceptable in service 0.05-0.1 Ra

c) Repolishing if over 0.1 Ra

Determination

of the pin/journal roughness

Measure the roughness with an

electronic roughness tester, or Evaluate the roughness with a Ruko tester, by

comparing the surface of the pin/journal with the specimens on the Ruko tester.

When performing this test, the pin surface and the Ruko tester must be

thoroughly clean and dry. Hold the tester close to the surface and compare the

surfaces. If necessary, use your finger nail to run over the pin/journal

surface and the Ruko specimens to compare and determine the roughness level.

BWM(bearing wear monitoring) Vs

OMD -A main

bearing damage was recently experienced on an MAN B&W S-MC-C main engine of

medium bore size. The damage was caused by a sudden ingress of foreign matter

into the bearing via the lubricating oil system, and it developed rapidly into

a bearing seizure.

Operation of the engine continued until the oil mist

detector (OMD) alarm set off and requested slow-down. At this stage, the

bearing damage had evolved into a situation where comprehensive repair of the

crankshaft and bearing housing (bedplate) was called for.

credit to man b&w service letter

Normally, main, crank pin and crosshead bearings

have very low wear rates. Wear rates up to 0.01 mm/10,000 hrs.

are considered acceptable, but lower values can be

expected under normal running conditions. Conversely, abnormal operating

conditions, e.g. pollution of the lubricating oil, scratches on journals or

spark erosion may give rise to significantly higher wear rates and ultimately

to bearing failure.

Continuous operation with an undetected bearing

failure may cause excessive heating, possibly damaging the shaft and bearing

housing. In particular, in case of a main bearing failure, the repair work may

become quite comprehensive.

To minimise the risk of bearing damage, and possible

consequential damage, inspection of the bearings is therefore recommended at

regular intervals.

External inspection of bearings

The following inspections are recommended to be

carried out at regular intervals.

Inside engine:

Bearing clearance measurements

Bearing edge check

Inspection of crankcase for

bearing metal

Crankshaft deflection measurement

Lubrication

system:

Inspection of oil filters

Oil analysis as described in the

“Operation” section of the instruction book.

Open-up inspection of

bearings

It is not recommended to open up bearings for

inspections unless this is found justified by the above-mentioned external

inspections or by other observations. The only exception is the open-up

inspection of crosshead bearings and crank pin bearings for every three piston

overhauls on engines not fitted with the monitoring systems(BWM)

Systems for monitoring and

protection of bearings

Recommended by MAN Diesel & Turbo (MDT) to

protect against bearing failure and consequential damage.

These can be categorised in two groups:

Bearing protection systems serving to detect particular

conditions of the bearing environment that may cause

bearing damage. MDT recommends Shaftline Earthing

Device Monitoring (SEDM) and Water In Oil Monitoring (WIOM).

Engine protection systems serving to detect a bearing damage

before it develops to cause damage to major parts of the engine. MDT recommends

Bearing Wear Monitoring (BWM) and Bearing Temperature Monitoring (BTM)

SEDM. Shaftline Earthing Device

Monitoring. A well-functioning shaft line earthing system is necessary to avoid

spark erosion in main bearings. Monitoring the electrical potential between

shaft and hull by a separate slip ring connected to

the alarm system ensures correct function of the system.

WIOM - Water In Oil Monitoring. In

several cases, water in the lubricating oil has resulted in poor bearing

performance. The lead-based overlayer used in crosshead bearings is sensitive

to water (corrosion), but also main bearings of both the White-Metal and

Tin-Aluminium types have been seen to suffer from water contamination.

BWM. Bearing Wear Monitoring is a

system that detects wear in any of the three crank train bearings, the main,

crank pin or crosshead bearings, by measuring the position of the crosshead

assembly in the bottom dead centre.

credit to man b&w service letter

The BWM system has threshold values for release of

alarm and engine slowdown, respectively.

BTM. Bearing Temperature Monitoring

systems have been available for MAN B&W engines for several years. A

variety in measuring principles and executions exists, but all systems serve to

release an alarm/slowdown when a bearing failure has developed to an extent

where heat is developed. (bearing housing design feature – bearing shells are

in place by interference fit, there is no relative movement of housing &

shell, effective heat transfer between shell & housing is essentail, cap

holding bolts are to be close pitched to prevent distortion, housing in robust

to prevent excessive strain on shell, housing is not too stiff to prevent

localized load concetration on bearing)

credit to diesel engine reference book

Types of bearing defects - 1.crack, 2. Fatigue failure of

white metal, 3.squeezing of white metal, so oil grooves are partially blocked,

4.wiping, 5. Faulty casting and faulty machining, 6.tin oxide corrosion, 7.acid

corrosion,8.thermal ratcheting, 9. Electrical potential, 10.fretting

Bearing damage cause –

Abrasion

This is still probably the most common form of

bearing damage, even though filtration standards are generally very high. Long

term operation with very fine debris in the oil, or short term operation with

coarser contaminant can result in abrasion and scoring of the surface of a

bearing roughening it to such an extent that overheating can occur due to the

surface roughness penetrating the thin oil film.

Fatigue

Typical fatigue damage of white metal is due to a

combination of load, high temperature, and the inconsistency of white metal

structure resulting from the direct lining of a large variable-cross-section

housing.

Corrosion

The different bearing alloys suffer corrosion under

different conditions. Tin-base white

metals, particularly in the slow-speed diesel engine, can form a hard,

dark (almost black) brittle surface

deposit when water is present in the lubricating

oil. Under these conditions, the bearing

becomes prone to overheating and seizure.

Alternatively, due to the brittle nature of the layer,

it can flake off the surface, leaving a generally

pitted appearance.

Copper-lead

lining, if

exposed to a lubricating oil which has thermally degraded to form organic acids

and peroxides, or become contaminated by sulphur containing fuel oils, blow-by

of products of combustion of such fuels, or cooling

water with antifreeze additives, is prone to corrosion of the lead phase of the

lining, be this either of the cast or sinter type.

Aluminium-based

linings are

completely resistant to engine oils, and to their high-temperature degradation

products. However, in direct contact with water, a film of aluminium oxide can

form in the bore, together with corrosion of the steel backing and possible

lifting of the lining material, although in an oil environment in an engine,

this is virtually impossible.

Service Letter SL05-460/NHN / November 2005 – corrosive wear

of crosshead bearing

Water in the lube oil system may lead to corrosive

wear of the overlayer and, eventually, mechanical damage to the crosshead

bearing, with high costs as a consequence. If the oil system becomes

contaminated with an amount of water exceeding our limit of 0.2% (0.5% for

short periods), acute corrosive wear of the crosshead bearing overlayer may

occur. The higher the water content, the faster the wear rate. A water content

higher than 1% could lead to critical damage within a few days in operation.

The overlayer in crosshead bearings consists of a thin, soft lead-tin-copper

galvanic alloy covering of the bearing lining metal. It is used in both

white-metal and AlSn40 (tin-aluminium) lined crosshead bearings. In AlSn40

bearings, the overlayer is always bonded to the bearing metal by a very thin interlayer

of Ni (nickel), or Ag (silver). There is no interlayer in white-metal based

bearings, but the risk of corrosion is still present. Wear of the overlayer

changes the geometry of the bearing surface and, thereby, the intended

"embedded arch" geometry. A change in the bearing geo-metry will

obstruct the oil film formation, which is critical for the correct functioning

of the crosshead bearing.

Furthermore, excessive wear of the overlayer in

AlSn40 bearings could, eventually, expose the interlayer to nickel-to-steel

contact with the cross-head pin, and result in scuffing action between the pin

and the bearing shell.

In

addition to damaging the compon-ents, there is, in extreme cases, a risk of a

crankcase explosion. AlSn40-based

crosshead bearings must urgently be replaced as soon as possible if an open-up

inspection shows more than 5% of the nickel layer exposed. If one bearing unit

has more than 5% of the Ni-layer exposed, it is very likely that all the other

units suffer from a similar extraordinary wear, and they should therefore be

replaced as well. To decide which bearings to inspect first, all top clearances

should be measured and compared with the shop test/sea trial records. If large

deviations are found, and/or if bearing "dust" is found in the

surrounding area in the frame box, those bearings should be the first to be

inspected.the lead content in the oil system can be used as a guideline: 0-4

ppm Normal, 5-10 ppm-Inspect filters and crankcase for bearing debris, and

prepare inspection of crosshead bearings when convenient, >10 ppm-Inspect

filters and crankcase for bearing debris, and prepare inspection of crosshead

bearings as soon as possible.

credit to man b&w service letter

Wiping

This type of damage can occur with any lining

material, and is caused by insufficient lubricating and cooling oil on the

bearing surface. This results in overheating and eventually melting of the

lowest melting-point phase of the lining alloy. Potential causes of

insufficient oil on the bearing

surface include inadequate generated oil film thickness,

insufficient clearance, housing distortion, restriction in oil supply system,

excessively worn bearings in other locations and

inadequate oil pump capacity.

Cavitation

Cavitation erosion damage to bearing surfaces is a

form of micro fatigue cracking, initiated by the collapse of vapour cavities.

Fretting

fretting of a bearing due to insufficient contact

pressure, local welding and tearing having

taken place between the bearing back and housing

bore, resulting in transfer of metal from one to the other. Where fretting of

the joint faces of the bearing occurs, this usually implies inadequate joint

face clamping force. Fretting of the housing joints can also be expected under

these conditions.Before fitting new bearings where fretting has occurred, all

trace of fretting build-up in the housing must be removed to avoid premature

catastrophic damage of the new bearing.

credit to man b&w service letter

This type of fretting was experience at L23/30H man

b& w engine --- (L23/30H man b& w engine (aux engine) main bearing

shell fretting - fretting/corrosion

between the main bearing shell and the main bearing cap on engines without main

bearing temperature sensors.The fretting/corrosion is caused by relative

movement between the bearing shell and cap during engine operation. The result

is that water and oil can migrate between the bearing shell and cap through the

sensor hole and cause the observed wear patterns on the bearing running

surface.( In order to stop further development of the fretting/corrosion, need to plug the hole in the main bearing cap and

fill the bore with a sealing compound; e.g. EN14AP.)

Design faults (above example of

L23/30H )

Major design faults will not generally be evident in

production engines because they would have been found out very quickly during

pre-production development testing

Incorrect assembly

The commonest causes of incorrect assembly are

associated with locating devices. Incorrect positioning will mean that oil feed

connections are misplaced and can block off the oil feed.

Incorrect location of a tang into its recess means

that the bearing back will not be in contact with the housing, and the

clearance between the bearing bore and the crankshaft can be lost, resulting in

local overheating of the bearing surface, and possibly seizure. Having located the

bearing correctly into its housing, care must be taken to ensure that the

housing bolts are correctly tensioned. Insufficient bolt load due to incorrect

tightening can result in the damage also excessive dynamic stressing of the

bolts and ultimate fatigue fracture. The bolts should also be tensioned in the

prescribed sequence given in the engine manual.

Environmental factors

Electrical discharge

- with

inadequate earthing, a discharge of current can occur through the oil

film between the journal surface and the bearing bore, resulting in

fine, cleanly defined

pitting of the bearing surface. Damage such

as this has been found to occur with an electrical potential in excess of only

50 mV.

Spark Erosion - Spark erosion is caused by a

voltage discharge between the main bearing and journal surface. The cause of

the potential is the development of a galvanic element between the ship’s hull,

sea water, and the propeller shaft/crankshaft. The oil film acts as a

dielectric. The puncture voltage in the bearing depends on the thickness of the

oil film. With increasing engine ratings, the specific load in the main bearing

is increased. This will reduce the oil film thickness, and enable the discharge

to take place at a lower voltage level. Since the hydrodynamic oil film

thickness varies through a rotation cycle, the discharge will take place at

roughly the same instant during each rotation cycle, i.e. when the film

thickness is at its minimum. The roughening will accordingly be concentrated in

certain areas on the journal surface. In the early stages, the roughened areas

can resemble pitting erosion - but later, as the roughness increases, the small

craters will scrape off and pick up white metal – hence the silvery white

appearance. Therefore, to ensure protection against spark erosion, the

potential level must be kept at maximum 80 mV, which is feasible today with a

high efficiency earthing device. If an earthing device is installed, its

effectiveness must be checked regularly. Spark erosion is only observed in main

bearings and main bearing journals. The

condition of the bearings must be evaluated to determine whether they can be

reconditioned or have to be discarded. Manufacturer is consulted.

credit to man b&w service letter

Journal wear ridge

Wear of the journal surface can occur due to

embedded hard contaminant in the bearing surface. Less wear occurs in the

region associated with grooves, gradually producing a ridge on

the journal surface,

which in turn causes wear of the bearing surface of partially grooved bearingsRidge wear will inevitably develop over time at the crank pin journal. The wear pattern is caused by abrasive impurities that remain in the lube oil. Efficient lube oil cleaning is therefore essential to keep the development of ridge wear as low as possible in trunk engines. Careful inspection and judgement of the crankpin journals must be carried out whenever a new crankpin bearing is installed.If ridge wear is observed, this must be rectified before new upper and lower bearing shells are installed.(need to ground down the crankpin to undersize to remove ridge wear)

Misalignment

Misalignment through whatever cause is typified by a

'D' pattern of wear, with the longest side on one end of the bearing, Causes

can be taper in the bearing housing or journal surface, debris trapped between

shell and housing, bruising of the steel backing of the bearing shell or

housing bore during assembly, taper through the bore of the bearing, or a

variation in alignment of a series of main bearing bores along the engine.

Geometric factors

Severe wear of localized regions of the bearing

surface are generally caused by specific geometric inaccuracies. Heavy wear in

the axial centre region is usually caused by a 'barrelled'

journal, whereas heavy wear at both ends of the

bearing results from an 'hour glass' profile.

Thermal

ratcheting –

caused by alternate cooling and heating of bearing, result in bearing

deformation, indication of high bearing temperature, most occurred at thrust

pad bearing surface.

Static fretting - The damage shown is caused by vibration of

a crankshaft within the bearing clearance. The term 'static' comes from the

fact that such damage only occurs when the engine is not running. The damage

can occur during transport of assembled engines to site. In marine

installations, generating sets mounted on flexible tank tops are prone to

similar damage. In such cases, the simplest palliative is to ensure that oil is

pumped through the bearing clearance every few hours while the engine is

inoperative(= must continuous run the pre-lube oil pump when stop

generator engine) ,

although in very severe instances it may also be necessary to redesign the

mountings (= installed on the resilience mounting).

Comments

Post a Comment